Fast delivery & high quality

Highly recommend purchasing this! Very good quality and this is already my third purchase for my watches. Definitely will buy from here as I have very bad experience with other brands' rubber straps. Great job Solitaire

Good value for a leather watch strap that serves its purpose with a vintage colour that is hard to find. Build quality is there for anyone who is not after the big brands.

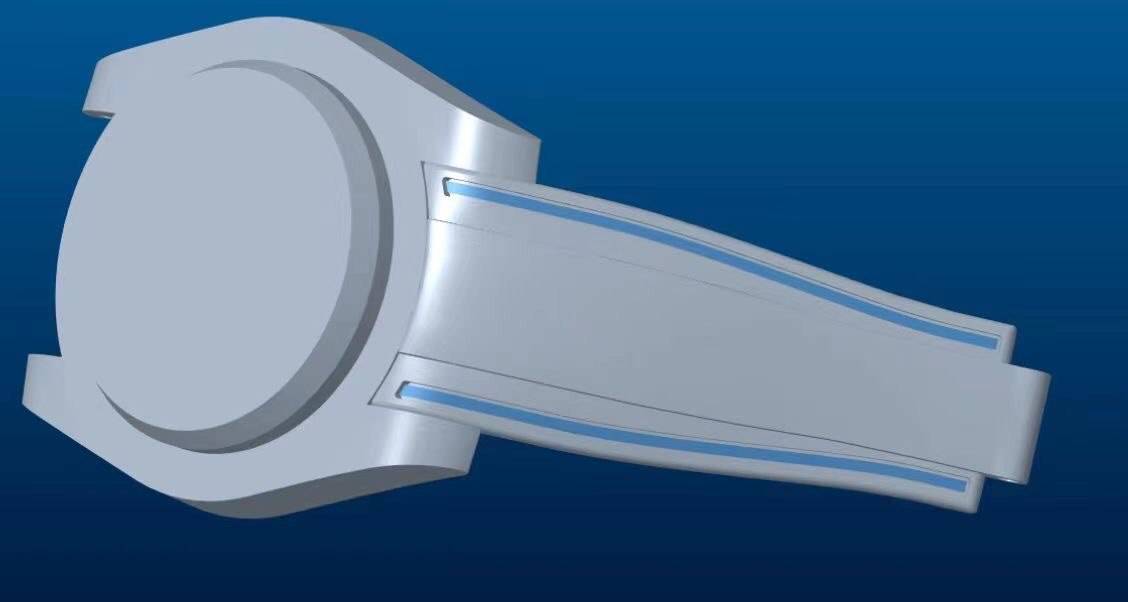

Really great rubber strap that comes with a tang buckle for my AP. Could never find this colour and quality anywhere else. Very much thanks to Solitaire Team!

Strap fits my Godzilla perfectly with my original clasp. Very comfortable

Good crocodile strap! Great quality with great pricing. Very worth it

I love the strap very much and the price is really affordable for a good quality genuine crocodile leather. Will purchase more.

This is indeed the BEST AP rubber strap I have ever come across. Love that Solitaire has an orange one and it looks great with my watch

Managed to find a grey rubber strap which is not easy to find in town. Fitting is perfect, love the quality very much!

Finally a change of look for my omega speedmaster strap. Love the range of straps available in store!